Loading...

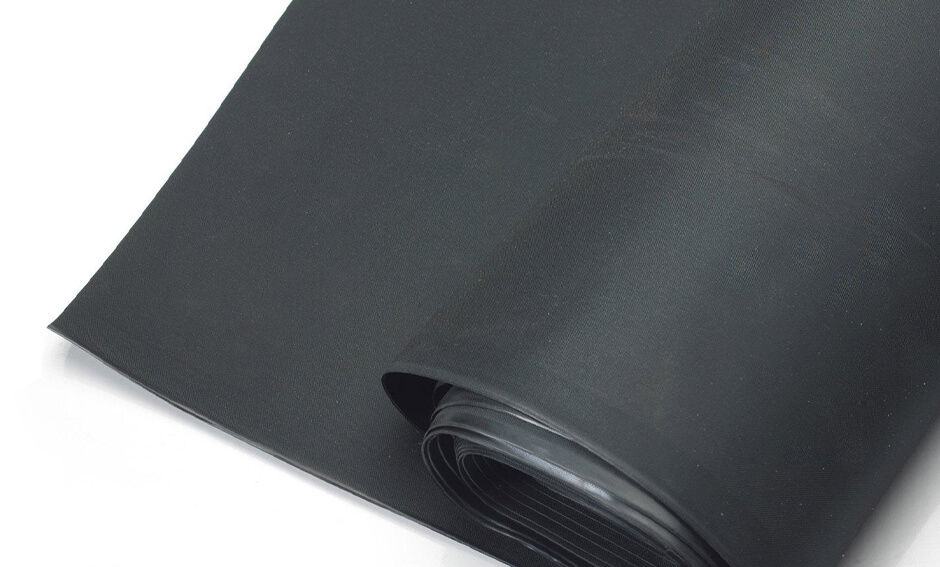

EPDM GEOMEMBRANES

"Based on success and continuity, honesty, trust and quality."

EPDM GEOMEMBRANES

Geomembrane whose elasticity has been increased is a rubber drastic waterproofing material which is manufactured from ethylene propen diene monomer. EPDM can be used in all projects that needs waterproofing.

EPDM GEOMEMBRANES TYPES

- A / EPDM

- A / EPDM - KL

• Terraces- Roofs

• Landscaping areas

• Artificial ponds, fire pools and other pools

• Building foundations

• Landscaping areas

• Artificial ponds, fire pools and other pools

• Building foundations

• Water tanks, irrigation channels

• Tunnels

• Dams

• Cut-and-cover tunnels

• Waste disposal areas

• Tunnels

• Dams

• Cut-and-cover tunnels

• Waste disposal areas

• Applicable as one layer

• Applications can be made by the help of hot wedge welders and hot air blowers

• Resistant to UV beams

• Resistant to plant roots

• Noncorrosive material, resistant to aging

• High performance in elongation and elasticity

• Applications can be made by the help of hot wedge welders and hot air blowers

• Resistant to UV beams

• Resistant to plant roots

• Noncorrosive material, resistant to aging

• High performance in elongation and elasticity

• Highly resistant to chemical materials

• Not harmful to environment, recyclable

• Long lived

• Resistant to cold weather conditions (-40 C°, +120 C°)

• Instantaneous temparature changes affect EPDM geomembrane at minimum rates

• Not harmful to environment, recyclable

• Long lived

• Resistant to cold weather conditions (-40 C°, +120 C°)

• Instantaneous temparature changes affect EPDM geomembrane at minimum rates

A / EPDM

It is manufactured with a thicknesses between 1, 1.2, 1.5, 2.0, 2.5, 3 mm. It is used in building foundations, terraces, ponds, canals, water reservoirs and pools. When it is demanded, it is manufactured as UV beam resistant. Width of the product is 2,05 meter; length is optional.A / EPDM - KL

It is a kind of EPDM geomembrane which is manufactured by laminating geotextile fabric onto the bottom of it. It is especially used for saving the extra time which is spent for spreading geotextile in construction site. It is also used in every kind of area where unlaminated geomembrane is used. It is manufactured by laminating geotextile fabric with various weight in grams. When it is demanded, it is manufactured as UV beam resistant. Width of the product is 2,05 meter; length is optional.TEST RESULTS ACCORDING TO THE TS EN 13361-13362-13491-13492-13493-13967

LONGTIDUNAL:181 N |

|||

LONGTIDUNAL:452 N/50 mm |

|||