Loading...

HDPE T-LOCK GEOMEMBRAN

"Based on success and continuity, honesty, trust and quality."

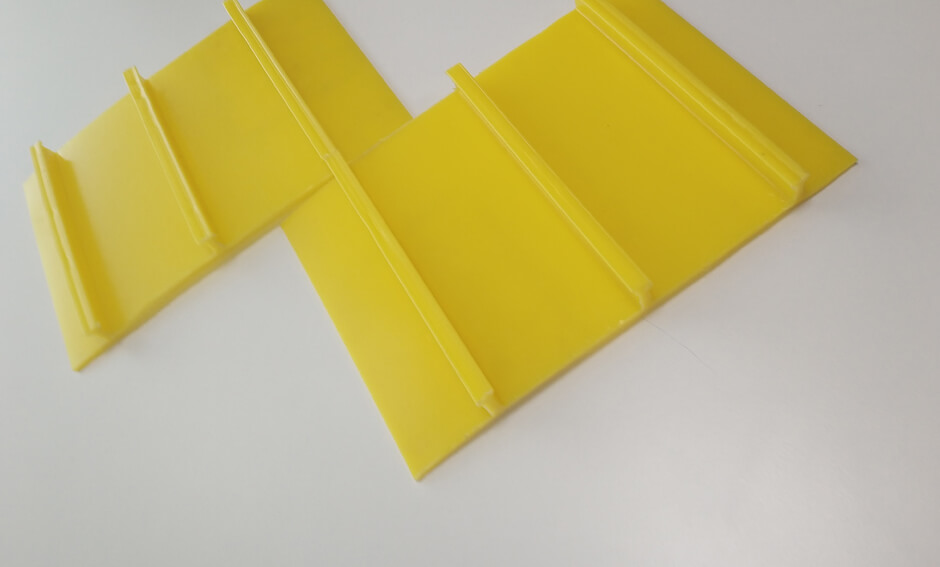

HDPE T-LOCK GEOMEMBRANE

It is made of HDPE. The unique feature that differentiate Geoser T-LOCK geomembrane is the continous T shape tabs on the surface. With these tabs, T-LOCK Geomembrane does not move in the concrete and prevents damages against concrete by blocking vibrations. Thus, the constructions shall be healtihier and more long-lived.

• Concrete pipes

• Irrigation canals

• Roofs

• Building foundations

• Irrigation canals

• Roofs

• Building foundations

• Tunnels

• Collector pipes

• Dams

• Waste sites

• Collector pipes

• Dams

• Waste sites

• The only difference between the T-Lock Geomembrane and the other Geomembrane are quotes. T-Lock Geomembrane can not act in concrete through these quotes, It prevents damage to the concrete from vibration.

• Highly resistance against chemicals.

• UV resistant.

• Higher tensile strength.

• Low permeability.

• Highly resistance against chemicals.

• UV resistant.

• Higher tensile strength.

• Low permeability.

• Profoundly resistant to the fractures and cracks.

• Superior protection against leakages.

• Resistant against natural condition.

• Highly resistant to organic and inorganic solvents.

• It is easily applied to any kind of ground.

• Optionally it can be reinforced geotextiles.

• Recycled and can be used again.

• Superior protection against leakages.

• Resistant against natural condition.

• Highly resistant to organic and inorganic solvents.

• It is easily applied to any kind of ground.

• Optionally it can be reinforced geotextiles.

• Recycled and can be used again.

It is combined with Fusion welding system (double-stitched hollow welding test), spreaded by leaving 6-10 cm ride share with free spreading technique. Fixed with pressure profiles in place finish.

| Name of Product | HDPE T-Lock |

| Product Content | High Density Polyethylene |

| Width-Length | Between 2,2-7 m -Desired height and dimensions |

| Thickness | Between 1-3 mm |

| Packing | In nylon packing-Tracked |

| Color | Black (Desired colors) |

| Standart No | TS EN 13967-13361-13362-13491-13492-13493 |

HDPE T-LOCK MECHNICAL AND CHEMICAL PROPERTIES

| Visible Defects (Cracks, scratches, tears, deformation) | TS EN 1850-2 | 2 Shouldn’t be visible defects | There are no visible defects. |

| Length | TS EN 1848-2 | Should be between registered tolerances | Registered values |

| Width | TS EN 1848-2 | Should be between registered tolerances | Registered values |

| Thickness | TS EN 1849-2 | Should be between registered tolerances | Registered values |

| Mass per unit area | TS EN 1849-2 | Should be between registered tolerances | Registered values |

| Density (g /cm3) | TS 1320 | Between 0,91-1,05 | 0.94 |

| Waterproofing (0,15 ar asınç !ltında) | EN 14150 | Must be waterproof | Waterproof |

| Tensile Strength (N/mm2), Min. | EN ISO 527 | Min. 26 N | 27 |

| Elongation Rate at Break (%), Min. | EN ISO 527 | Min. %700 | 710 |

| Resistance to Weather Conditions (%) | EN 12224 | Between 1-10 | 4% |

| Resistance to Oxidation (%) | EN 14575 | Max. %5 | 2% |

| Gas Tightness | ASTM D 1434 | NPD | NPD |

| Tear Strength (kN/m) | ISO 34-1 | Between 166-220 | 190 |

| Resistance Against Hot and Cold (Waiting 10 min. At 80 ° and -30 °) | DIN 53361 | No cracks and tears | There is no tearing and cracking. |

| Combustion Class | TS EN 13501 | Classification | Class E |

| Flexibility in the cold | EN 495-5 | No break and crack | There is no breaking or cracking. |