Loading...

POLYETHYLENE GEOMEMBRANES

"Based on success and continuity, honesty, trust and quality."

POLYETHYLENE GEOMEMBRANES

Polyethylene(PE) takes the name of ethylene which is in the form of monomer. With several methods of polymerization, Ethylene becomes Polyethylene. Geoser HDPE Geomembrane is a geosynthetic liner which is formed as a result of extrusion of high density polyethylene and shaped homogenously by calender system. It can be used in all projects where impermeability is required.

POLYETHYLENE GEOMEMBRAN TYPES

- HDPE Flat Geomembranes

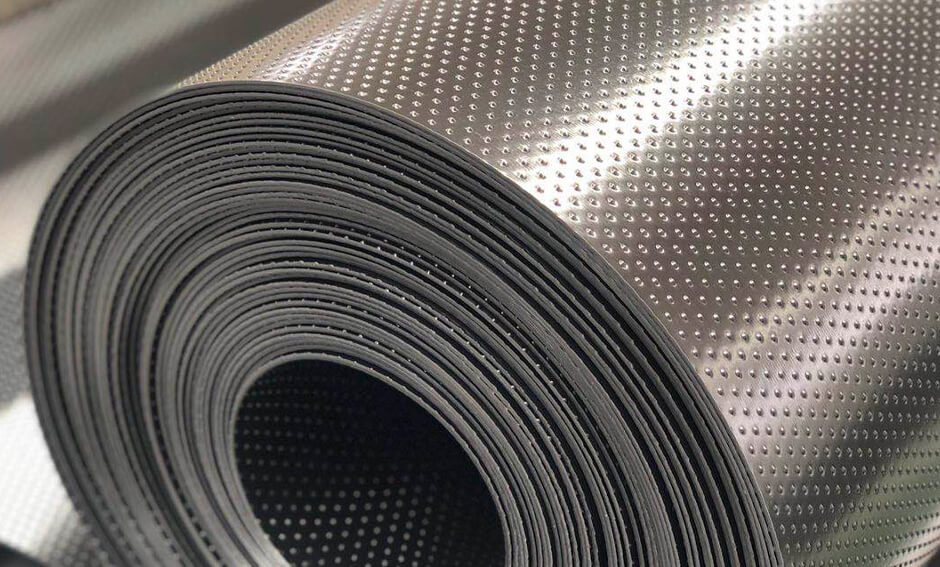

- HDPE one-side textured geomembranes

- HDPE two-side textured geomembranes

- LDPE geomembranes

- LLDPE geomembranes

- VLDPE geomembranes

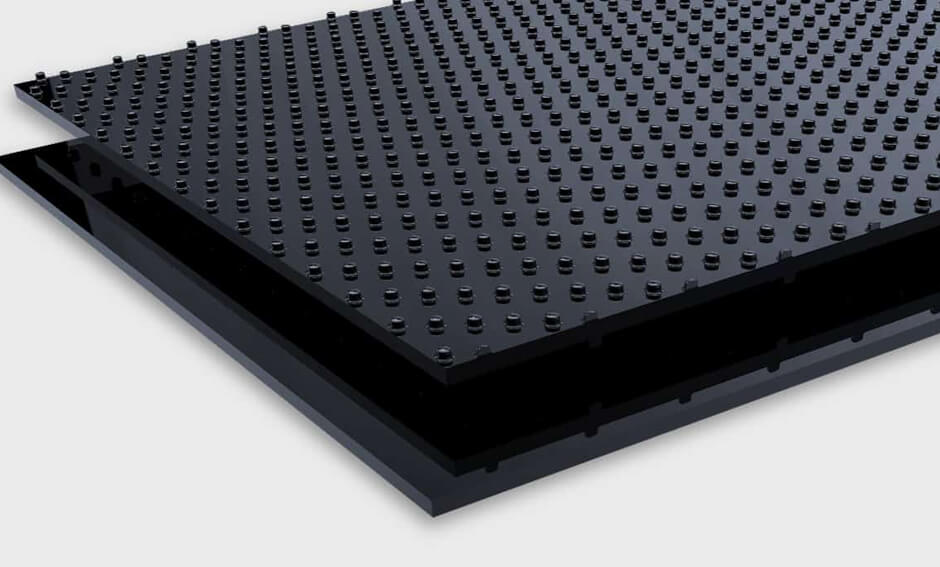

- HDPE T-Lock geomembranes

- HDPE Discrete T-Lock geomembranes

- HDPE one-side geotextile laminated geomembrane

• Landfills

• Waste water repository and treatment

• Drainage pits for collecting leakage of gold and other mines

• Oil tanks and oil fields

• Sedimentation ponds

• Waste water repository and treatment

• Drainage pits for collecting leakage of gold and other mines

• Oil tanks and oil fields

• Sedimentation ponds

• Fertilizer pits

• Building foundations, if needed

• Irrigation ponds

• Tunnels

• Irrigation canals

• Bioenergy generation plants

• Building foundations, if needed

• Irrigation ponds

• Tunnels

• Irrigation canals

• Bioenergy generation plants

• High resistance to chemicals

• UV resistant

• Less friction rate because of the textured layer

• Highly resistant to organic and inorganic solvents

• UV resistant

• Less friction rate because of the textured layer

• Highly resistant to organic and inorganic solvents

• Profoundly resistant to the fractures

• Resistant against natural conditions

• Resistant to punctures and cracks

• Low permeability

• Higher tensile strength

• Resistant against natural conditions

• Resistant to punctures and cracks

• Low permeability

• Higher tensile strength

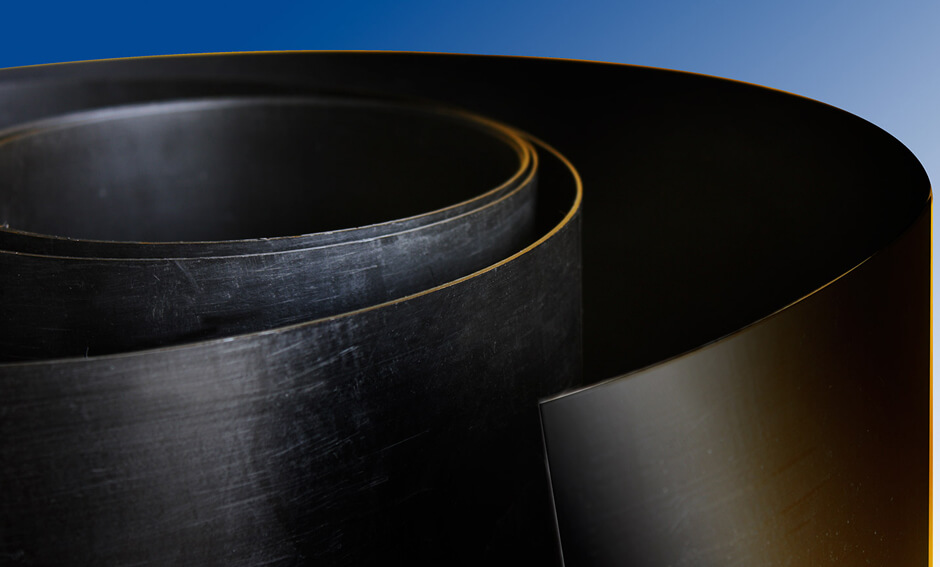

Geoser / HDPE

It is a kind of geomembrane made of high density polyethylene raw material and generally used in landfills; chemical repository sites. Although it is hard, it is not fractured. It is manufactured in a width of 2,10m to 7,00mt; standart lengths of 50m to 100m or optional lengths; in optional colours; with thicknesses of 1,00mm&1, 20mm&1, 50mm& 2,00mm&2, 50mm&3,00mm.Geoser / LDPE

It is a kind of geomembrane made of low density polyethylene raw material and generally used in landfills; waste water repository sites and irrigation ponds. It has a softer form than HDPE geomembranes. It is manufactured in a width of 2,10m to 7,00mt; standart lengths of 50m to 100m or optional lengths; in optional colours; with thicknesses of 1,00mm&1,20mm&1,50mm& 2,00mm&2,50mm&3,00mm.Geoser / LLDPE

It is a kind of geomembrane made of linear low density polyethylene raw material and generally used in ornamental ponds and irrigation canals. It has the softest form in types of polyethylene geomembrane. It is manufactured in a width of 2,10m to 7,00mt; standart lengths of 50m to 100m or optional lengths; in optional colours; with thicknesses of 1,00mm&1,20mm&1,50mm& 2,00mm&2,50mm&3,00mm.Geoser / VLDPE

It is a kind of geomembrane made of the lowest density polyethylene raw material and generally used in ponds and water reservoirs. It is manufactured in optional colours and with thicknesses of 1,00mm&1,20mm&1,50mm& 2,00mm&2,50mm&3,00mm.POLYETHYLENE GEOMEMBRANE SPECIFICATION TABLE

| THICKNESS | EN1849-2 | mm | 1,0 mm | 1,5 mm | 2,0 mm | 2,5 mm | 3,0 mm |

| DENSITY | EN ISO 1183-1 | gr/m³ | 0,935-0,965 | 0,935-0,965 | 0,935-0,965 | 0,935-0,965 | 0,935-0,965 |

| MASS PER UNIT AREA | EN1849-2 | gr/m² | 940 | 1410 | 1880 | 2350 | 2820 |

| TENSİLE STRENGTH OF FLUXİNG | EN ISO 527 | N/mm² | >16 | >16 | >16 | >16 | >16 |

| ELONGATION AT FLUXING | EN ISO 527 | % | >12 | >12 | >12 | >12 | >12 |

| TENSILE STRENGTH AT BREAK | EN ISO 527 | N/mm² | >26 | >26 | >26 | >26 | >26 |

| ELONGATION RATE AT BREAK | EN ISO 527 | % | >700 | >700 | >700 | >700 | >700 |

| STATIC PUNCTURE | EN ISO 12236 | N | 2400 | 3700 | 4900 | 6050 | 7200 |

| TEAR STRENGTH | ISO 34-1 | N/mm | >130 | >140 | >140 | >140 | >140 |

| SHEAR STRENGTH | EN1849-2 | gr/m² | 940 | 1410 | 1880 | 2350 | 2820 |

| PEEL STRENGTH | ASTM 6392 | N/25mm | 350 | 525 | 701 | 876 | 1050 |

| WATER THIGHTNESS | EN 14150 | m³/m².gün | <10-6 | <10-6 | <10-6 | <10-6 | <10-6 |

| CARBON BLACK CONTENT | ASTM D 1603 | % | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 |

| CARBON BLACK DISSIPATION | ASTM D 5596 | KATEGORİ | 1/2b | 1/2b | 1/2b | 1/2b | 1/2b |

| MELT FLOW INDEX | EN ISO 1133 | gr/10 min | 2,16 kg 190 0C ;<1 5,0 kg 190 0C; <3 |

2,16 kg 190 0C ;<1 5,0 kg 190 0C; <3 |

2,16 kg 190 0C ;<1 5,0 kg 190 0C; <3 |

2,16 kg 190 0C ;<1 5,0 kg 190 0C; <3 |

2,16 kg 190 0C ;<1 5,0 kg 190 0C; <3 |

| DETERMINATION OF THE RESISTANCE TO WEATHERING | EN 12224 | % | <25 | <25 | <25 | <25 | <25 |

| RESISTANCE TO OXIDATION | EN 14575 | % | <25 | <25 | <25 | <25 | <25 |

| RESISTANCE TO STATIC LOAD | EN14576 ASTM D 5397 |

h | >200 | >200 | >200 | >200 | >200 |

| OXIDATIVE INDUCTION TIME | ASTM D 3895 | >100 | >100 | >100 | >100 | >100 | >100 |

| COMBUSTION CLASS | EN ISO 11925-2 | - | Class E | Class E | Class E | Class E | Class E |

| DETERMINATION OF RESISTANCE TO SOLIDLIQUID EXTRACTION | EN 14415 | % | METOD A,B; <5 METOD C; <25 |

METOD A,B; <5 METOD C; <25 |

METOD A,B; <5 METOD C; <25 |

METOD A,B; <5 METOD C; <25 |

METOD A,B; <5 METOD C; <25 |