Loading...

PVC Geomembranes

"Based on success and continuity, honesty, trust and quality."

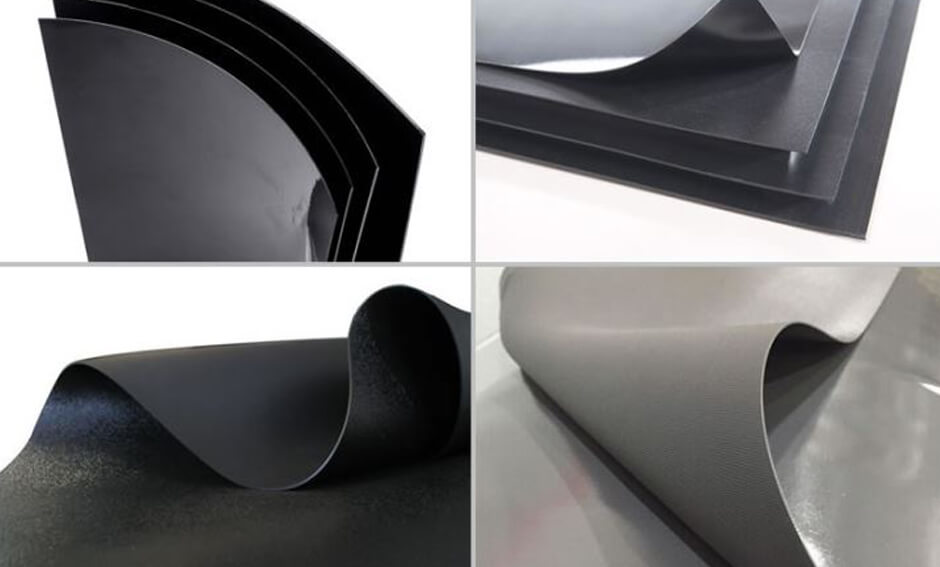

PVC Geomembranes

PVC geomembrane can be produced by PVC polymers. PVC geomembranes can be applied in many industries, such as waste landfills anti-seepage, water management, reservoirs anti-seepage projects, etc. In recent years, with the development of geomembranes material science and the improvement of geomembranes performance, the application of geomembranes has become more extensive and the scale of their use has become larger and larger. Geomembranes are gradually popular with engineering personnel due to their advantages of easier construction, shorter construction period, and lower cost.

PVC GEOMEMBRANE TYPES

- Tunnel Type Layer Signal PVC Geomembrane

- Uv resıstant PVC Geomembrane

- Flat Type PVC Geomembrane

- Antibacterial PVC Geomembrane

• Building Foundations

• Dams, transmission tunnels

• Roofs and terraces

• Carparks

• Waste water treatments

• Pools

• Dams, transmission tunnels

• Roofs and terraces

• Carparks

• Waste water treatments

• Pools

• Pond for agricultural irrigation purposes

• Potable water reservoirs

• Underpasses

• Otoparklar

• Highway, railway tunnels

• Subway stations and tunnels

• Irrigation canals

• Potable water reservoirs

• Underpasses

• Otoparklar

• Highway, railway tunnels

• Subway stations and tunnels

• Irrigation canals

• Resistant to plant roots.

• Can be recycled.

• Resistant to temperatures between -40C and +70C.

• Joints are welded with welding robots which can do double inlet welding.

• Resistant to aging and corrusion.

• Enclosed class “E” in combustion, no flame occurs.

• Long life span.

• Can be recycled.

• Resistant to temperatures between -40C and +70C.

• Joints are welded with welding robots which can do double inlet welding.

• Resistant to aging and corrusion.

• Enclosed class “E” in combustion, no flame occurs.

• Long life span.

• High resistance to mechanic shocks.

• High performance in tensile strength, elongation and elasticity.

• Keeps high eleasticity in cold weather conditions, never cracks.

• Can be manufactured as lamination with geotextile fabric; UV beam resistant, signal layered (OPTIONAL).

• Since it is loose laid, it is affected at the minimum degree as a result of movement in construction.

• Different colour and dimension options.

• High performance in tensile strength, elongation and elasticity.

• Keeps high eleasticity in cold weather conditions, never cracks.

• Can be manufactured as lamination with geotextile fabric; UV beam resistant, signal layered (OPTIONAL).

• Since it is loose laid, it is affected at the minimum degree as a result of movement in construction.

• Different colour and dimension options.

Tunnel Type Layer Signal PVC Geomembrane

It is a signal layered PVC geomembrane with its special PVC formulation; increased elongation and tensile strength. It is generally used in Highway, Subway, Railway Tunnels. Here, signal layer property works in order to detect any kind of defect or damages on the yellow or gray coloured surface of geomembrane. So that, modification can easily be made for that region. They are manufactured in YellowBlack, Gray- Black or optional colours. Geoser PVC GEOMEMBRANES are manufactured in a width of 2,10m; standard lengths of 20m&25m; with thicknesses of 1,00mm &1,20mm &1,50mm &2,00mm &2,50mm &3,00mm. When it is demanded, they are manufactured in optional lengths.Flat Type PVC Geomembrane

It is made of PVC. It has standard PVC geomembrane features. With its higher strength, it has higher performance in resistance to plant roots. It is manufactured in optional colours.Uv resıstant PVC Geomembrane

It is made of PVC. Since it is manufactured as UV Beam Resistant, it is called “Pond Type” Geomembrane. Because of UV additive, it is direct sun beam resistant for ages. That kind of Geoser PVC Geomembrane is comfortabely used without coating the surface of it. It is manufactured in gray, blue, yellow coloursGeoser PVC GEOMEMBRANES are manufactured in a width of 2,10m; standard lengths of 20m&25m; with thicknesses of 1,00mm & 1,20mm & 1,50mm & 2,00mm & 2,50mm & 3,00mm. When it is demanded, they are manufactured in optional lengths.

Antibacterial PVC Geomembrane

It is especially used in potable water reservoirs. Special nanotech additives are used during its manufacturing process. Since it helps to avoid bacteria reproduction, it can be comfortabley used. Generally, it is in gray or blue colour.PVC GEOMEMBRANE SPECIFICATION TABLE

| THICKNESS | 1,00 mm minimum | DIN 53370 |

| TENSILE STRENGTH | 15 N/mm² minimum | DIN 53455 |

| ELONGATION AT BREAK | %250 minimum | DIN 53455 |

| BREAK RESISTANCE AT 20% UNIT ELONGATION | 2,5 N/mm² | DIN 53454 |

| SPREAD TEAR STRENGTH | 100 N/mm minimum | DIN 53363 |

| WATER PRESSURE STRENGTH | At 10 Bar For 10 Hours | DIN 16726 |

| WELDED JOINT STRENGTH | 13,5 N/mm² minimum | DIN 16726 |

| DIMENSIONAL STABILITY AFTER RAPID AGING | ±%2 maksimum | DIN 16726 |

| MATERIAL PROPERTIES DURING AND AFTER 80ºC STORAGE: | DIN 16726 | |

| a. Overview | No Bubbles | |

| b. Dimensional stability, longitudinal and transverse | <-%3 | |

| c. Change in tensile strength, longitudinal and transverse | <±%20 | |

| d. Change in Elongation at break, longitudinal and transverse | <±%20 | |

| e. Folding At -20 ºC | No Cracks | |

| Changes After Stored in Acid And/Or Alcaline Solutions: | DIN 16726 | |

| a. Change in tensile strength, longitudinal and transverse | <±%20 | |

| b. CHANGE IN ELONGATION PER UNIT | 100 N/mm minimum | DIN 53363 |

| c. Folding at -20 ºC | No Cracks | |

| Shear Resistance, Bitumen Annex | 100 N / 50 mm | DIN 16726 |

| Punchinh Test Behaviours | No Punching at 750mm Height | DIN 50014 |

| Water Absorption | Max. %1 | DIN 53495 |